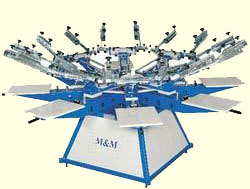

Our Factories are

well equipped with the latest state of the art imported Machineries. A

modern state-of-the-art machineries are available in-house to make sure

that quality is always delivered at every stage of production. We have

Total Sewing Machines 300 Nos and Finishing 30 Nos.

The key to run any smooth manufacturing operations lies in the effective

establishment & governance of infrastructure. At KARPAGHAM TEX (K TEX)

, We have

well equipped departments to handle various aspects of operations from

merchandising & sampling to testing. From planning to delivery, each of

these individual departments is integrated & assimilated into a well-knit

setup that thrives on speed and perfection.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||